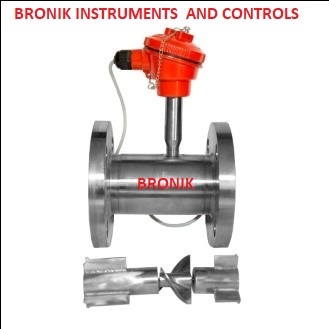

Oil Flow Sensor

Price 15000 INR/ Piece

Oil Flow Sensor Specification

- Diameter

- DN15, DN20, DN25

- Humidity %

- 0%95% RH

- Flow Rate

- 0.5-100 L/min

- Resolution

- 0.01 L/min

- Sensor Type

- Turbine Flow Sensor

- Connectivity Type

- Threaded Connection (BSP/NPT)

- Protection

- IP65

- Temperature Range

- -20C to 80C

- Frequency

- Pulse Output

- Measurement Range

- 0.5 to 100 L/min

- Capacity

- High Flow Handling

- Application Media

- Oil (Hydraulic, Lubricating, Diesel, etc.)

- Current Range

- 4-20 mA Output

- Pressure Range

- Max 16 Bar

- Material

- Aluminum Alloy Body

- Power Supply

- 24V DC

- Power Consumption

- < 2W

- Accuracy

- 1% F.S.

- Display Type

- Digital LCD

- Range

- 0.5 to 100 L/min

- Min. Working Pressure

- 0.2 Bar

- Response Time

- <0.3s

- Equipment Type

- Oil Flow Sensor

- Max. Working Pressure

- 16 Bar

- Power Indicator

- LED Indicator Present

- Storage Temperature

- -40°C to 85°C

- Communication Interface

- RS485 (Optional)

- Output Signal

- 4-20 mA, Pulse

- Repeatability

- 0.2%

- Applicable Viscosity

- Max 200 cSt

- Cable Length

- 2 meters (Standard)

- Weight

- Approx. 0.8 kg

- Mounting Position

- Horizontal or Vertical

- Ingress Protection

- IP65

- Ambient Temperature

- -10°C to 55°C

Oil Flow Sensor Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Week

About Oil Flow Sensor

Other Details

MOC :- S.S.316

Rotor :- S.S.410

Shaft : Hard StainlessSteel-316 With Carbon Bush

Accuracy :- 1 % FSD

Temp :- ( - 20 To 120Degree )

Working Pressure :- 60Bar

O/P:- Pulse ( NPN Open CollectorReliable Performance Across Industrial Environments

Built with an aluminum alloy body and IP65 rating, this flow sensor withstands harsh working conditions. It functions efficiently in temperatures from -20C to 80C and high humidity (0%-95% RH), making it ideal for diverse industrial settings, including manufacturing plants and refineries across India.

Versatile Output and Advanced Connectivity

The sensor offers 4-20 mA analog output, pulse signal, and optional RS485 digital communication. This flexibility ensures seamless integration into existing control systems and accurate feedback for process automation. Threaded BSP/NPT connections and a 2-meter standard cable simplify installation and connectivity.

Precision Measurement for Enhanced Process Control

With an impressive repeatability of 0.2% and a measurement accuracy of 1% F.S., this device provides consistent flow data. Its fast response time (<0.3s) and high-resolution digital LCD display enable real-time monitoring for improved operational efficiency.

FAQ's of Oil Flow Sensor:

Q: How is the Oil Flow Sensor installed and in what mounting positions is it suitable?

A: The oil flow sensor can be installed in both horizontal and vertical pipe orientations, offering flexibility for various piping layouts. It uses threaded connections (BSP/NPT) for secure attachment and comes with a standard 2-meter cable for convenient wiring.Q: What types of output signals does the Oil Flow Sensor provide?

A: This sensor supports multiple output signal options: analog 4-20 mA, pulse output, and optional RS485 communication interface. These outputs facilitate integration with different monitoring and automation systems, enhancing process adaptability.Q: When should I use this Oil Flow Sensor and what media is it compatible with?

A: The sensor is suitable whenever accurate and real-time oil flow measurement is required, including hydraulic, lubricating, and diesel oil applications. It is designed to handle fluids with a viscosity up to 200 cSt, making it ideal for industrial monitoring and control processes.Q: What is the process for reading measurements and monitoring sensor status?

A: Users can monitor real-time flow rates via the digital LCD display, which shows data with a resolution of 0.01 L/min. The built-in LED power indicator provides immediate visual confirmation of operation status for quick diagnostics.Q: What are the main benefits of using this Oil Flow Sensor in industrial settings?

A: Key benefits include high measurement precision (1% F.S.), robust construction (IP65, aluminum body), quick response (less than 0.3s), versatile output options, and easy integration for increased operational reliability and process efficiency.Q: Where can this sensor be used and what are its protection features?

A: This sensor is built for industrial environments such as factories, refineries, and large machinery setups across India. With an IP65 ingress protection rating and wide temperature tolerance, it reliably operates in tough and variable conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Flow Meter Category

Clamp Type Ultrasonic Flow Meter

Minimum Order Quantity : 10 Pieces

Usage : Liquid Measurement

Display Type : Digital Only

Product Type : Clamp type Ultrasonic Flow Meter

Power Supply : 230vac

Industrial Flow Meter

Price 55500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Liquid Measurement

Display Type : Digital Only

Product Type : Handheld Ultrasonic Flow Meter

Power Supply : Battery Power

Coriolis Mass Flow Meter

Price 210000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Display Type : Digital Only

Product Type : Coriolis Mass Flow Meter

Power Supply : Water

Digital In-Line Flow Meter

Price 31000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Display Type : Digital Only

Product Type : Digital InLine Flow Meter

Power Supply : Water

GST : 33CJMPR5841P1ZE

|

BRONIK INSTRUMENTS AND CONTROLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry